Update 2022: We are still hoping to use recycled plastic in the future, but due to overwhelming demand for our lights, we had to speed up the development of the new light case and have invested in a new mould allowing us to produce hundreds of light cases quickly. Our light cases are very durable and last indefinitely, protecting the components inside. Alongside our repair and replace guarantee, our lights have a minimal impact on emissions, and save at least 92kg of carbon per year, when used instead of kerosene lights.

The Mwezi solar light is at the heart of the Mwezi Foundation. The light’s design was developed by us, and we refined it to ensure that it was easy to dismantle and fix. This was to guarantee that the process of refurbishing and replacing the lights would be straightforward, thereby reducing waste. However, we are always looking for ways to make our work even more sustainable – and that’s why we’ve been working on a brand new Mwezi solar light, which will be made from recycled plastic!

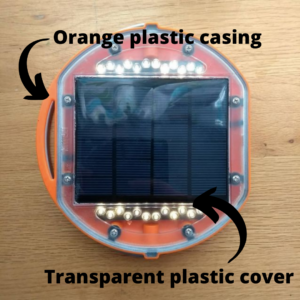

Currently, our solar lights are made out of transparent plastic covers and orange plastic casings, as you can see below:

However, we are running out of this stock of orange plastic casings, and once it has run out, we want to begin producing new stock from recycled plastic.

Currently, our lights are manufactured in our workshop in Likoni, Kenya. We want to ensure that this is also the case for our new stock of lights. This will eliminate the need to transport solar lights from another area of the world, reducing air miles. In addition, it will ensure that the manufacturing process provides local employment in Kenya.

The New Design:

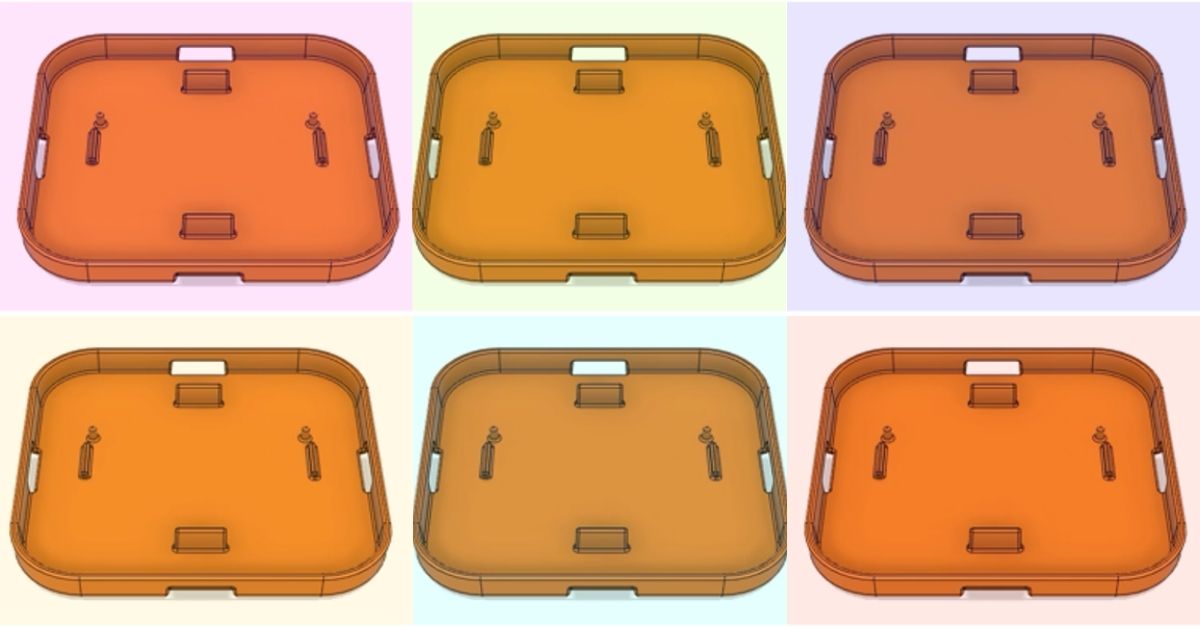

Product designer, Will Durrigan, has kindly been supporting the Mwezi Foundation on this project by offering his expertise at no cost. He has produced several prototype designs for us, all of which can be 3D-printed to give us a three-dimensional impression of the end result. The designs all have a flat, clear Perspex top, which enables the solar panel to charge whilst also allowing sunlight to shine through the top of the light brightly. The light’s casing would be made from recycled plastic.

To minimise our waste further, we have simplified the design of the lights so that they require as few components as possible. Moreover, we are trying to make the components out of materials which are readily available, such as coat-hangers.

We will make our recycled orange casings using Precious Plastic machines. Precious Plastic (PP) is a plastic recycling project. They develop machines which enable people to work with old, used plastic and transform it into something new and valuable. They share the blueprints for these machines online, as well as video tutorials about how to use them. Their machines are designed to be made in remote areas and often out of available scrap material, so that they can be created anywhere in the world. Our aim is to eventually have these machines in our workshop in Likoni, so that our technical manager, John, can start using them there.

Precious Plastic (PP) Machines:

- The Plastic Shredder: The Shredder cuts up old plastic items into small shards, which we can then turn into light casings.

- The Injection Moulding Machine: The Injection Moulding machine heats up the shredded plastic shards and injects them into our aluminium moulds. The plastic then cools down and solidifies in the mould, creating our light casings! Will has created a prototype design for a mould, and this can also be 3D-printed. If we are satisfied with the result, we will replicate the mould in aluminium and begin using it.

We are so excited to get working on this project to make the Mwezi Solar light more sustainable and environmentally friendly than ever!

Update (Jan 2022): The plastic case has been redesigned and the first stock is being shipped to Mombasa. Our intention eventually is to be able to use recycled plastic to make these, but given the huge demand for lights, and a fire in the workshop where the Precious Plastics project was being developed, it was important for us to produce the cases as quickly as possible. Given the investment required in the redevelopment, we will use these new cases for several years. However, our intention is to move to recycled plastic in the long run, and this article explains how we intend to do it.